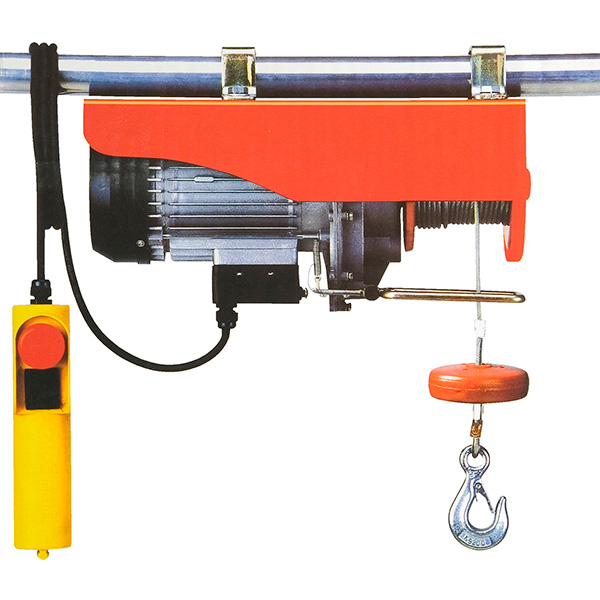

Proper training for electric hoist operators is of paramount importance in ensuring workplace safety, efficiency, and productivity. Electric hoists are powerful machines designed to lift heavy loads, and when operated incorrectly, they pose significant risks to both the operator and others in the vicinity. Therefore, comprehensive training programs are essential to equip operators with the necessary knowledge and skills to operate these devices safely. First, proper training ensures the safety of operators and those working around them. Electric hoists have the potential to cause serious injuries or fatalities if mishandled. By providing operators with thorough training, they learn how to use the equipment safely, including understanding its capabilities and limitations, and proper lifting techniques. They also learn about potential hazards such as overloading, improper rigging, and environmental factors like wind or uneven ground, and how to mitigate these risks effectively. With this knowledge, operators can make informed decisions to prevent accidents and ensure the safety of themselves and their colleagues.

Moreover, proper training enhances operational efficiency and productivity. A well-trained operator can perform tasks more efficiently, minimizing downtime and maximizing productivity. Through training, operators become familiar with the equipment controls and functions, enabling them to operate the hoist smoothly and effectively. They also learn how to inspect the equipment for any signs of damage or malfunction, allowing for early detection and prevention of potential issues that could disrupt operations. Additionally, trained operators are better equipped to handle unexpected situations or emergencies, reducing the likelihood of delays or accidents that could affect productivity. Furthermore, training contributes to equipment longevity and cost savings. Electric hoists are valuable assets, and proper maintenance is essential to prolong their lifespan and prevent costly repairs or replacements. Trained operators understand the importance of regular maintenance tasks such as lubrication, inspection, and minor repairs, which can help prevent premature wear and extend the life of the equipment.

By following proper procedures and best practices learned during training, operators can help ensure that the hoists remain in optimal condition, reducing downtime and minimizing repair costs over time. In addition to safety, efficiency, and cost savings, proper training also promotes compliance with relevant regulations and standards. Many industries have specific guidelines and requirements for the operation of lifting equipment, and failure to comply can result in fines, penalties, or even legal action. By providing comprehensive training programs, employers can ensure that their operators are knowledgeable about relevant regulations and standards, reducing the risk of non-compliance and associated consequences. In conclusion, proper training for polipasto electrico operators is crucial for ensuring workplace safety, operational efficiency, equipment longevity, and regulatory compliance. Investing in comprehensive training programs not only protects the well-being of operators and others in the workplace but also contributes to overall productivity and cost savings. By prioritizing training and empowering operators with the necessary skills and knowledge, employers can create a safer, more efficient, and compliant work environment.